Pharmaceutical Packaging Design

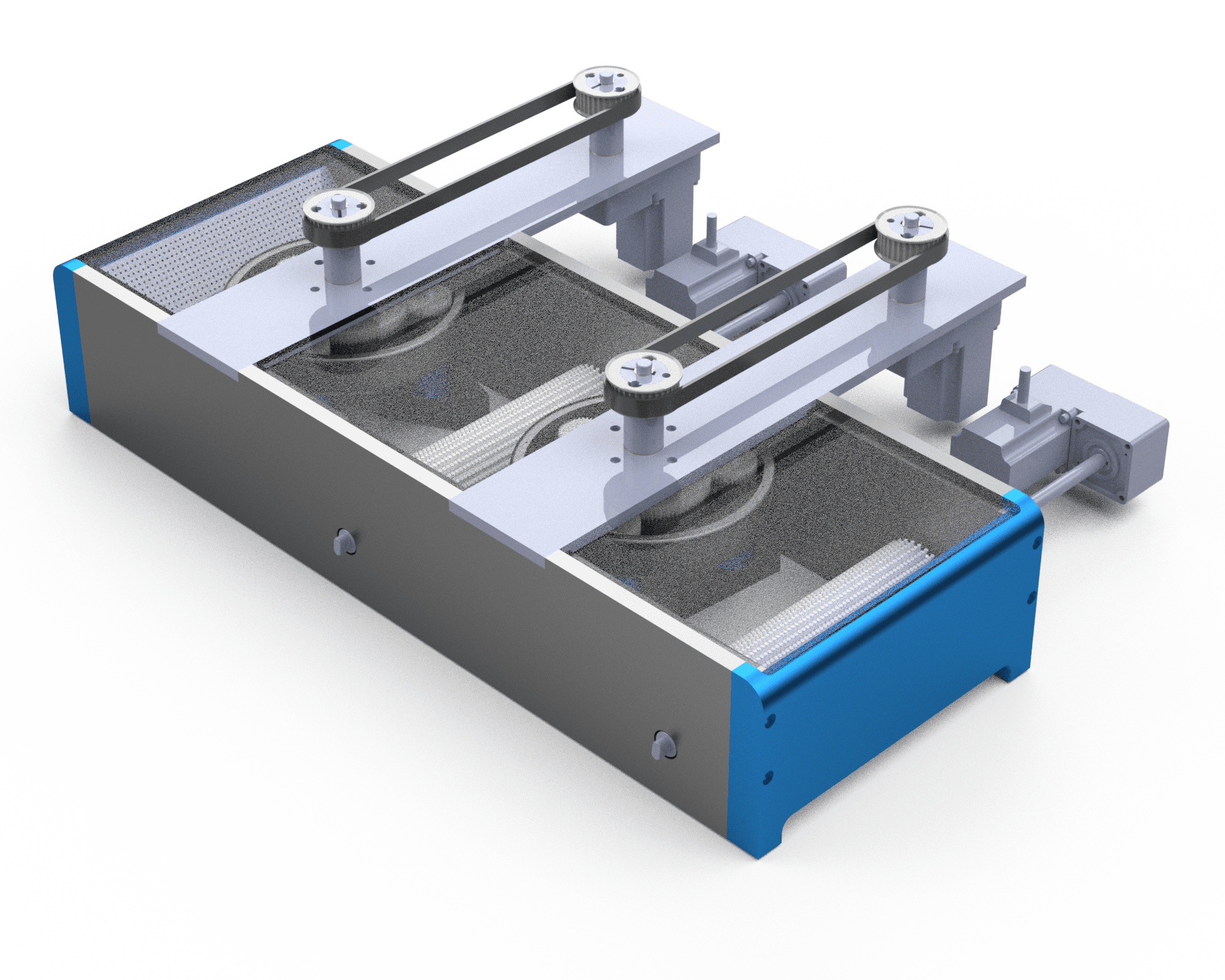

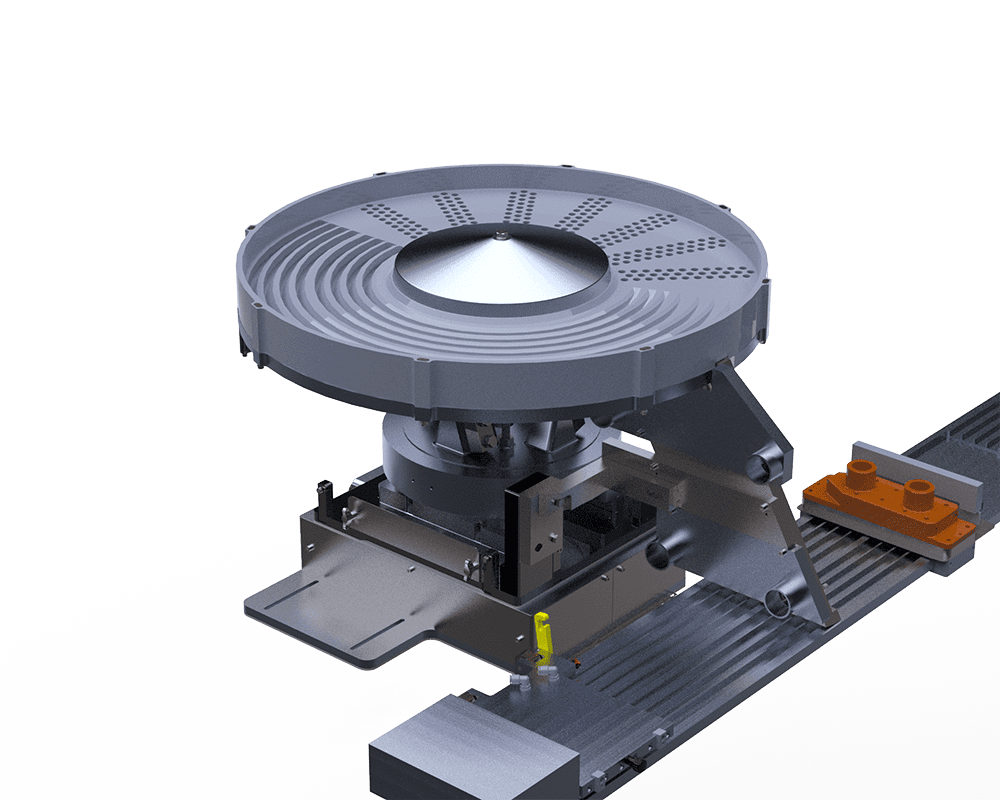

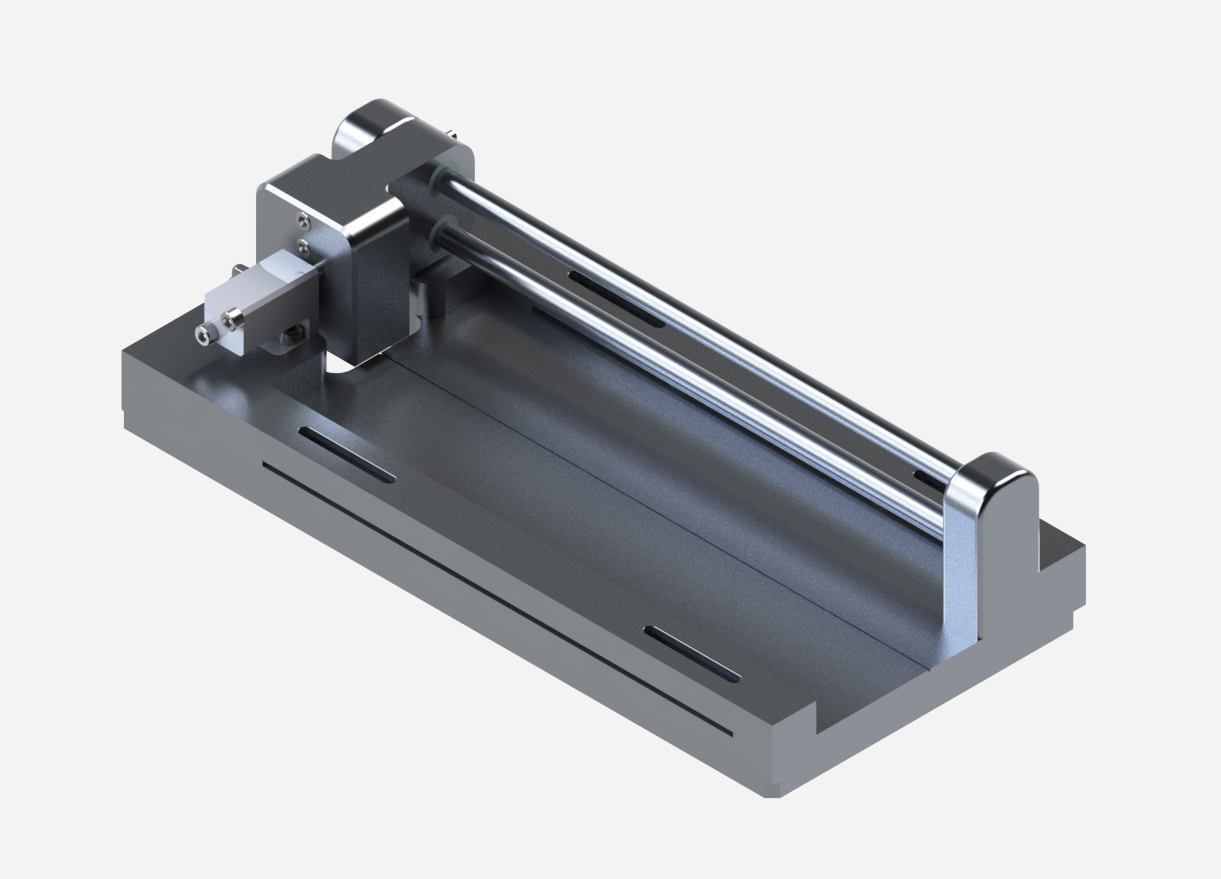

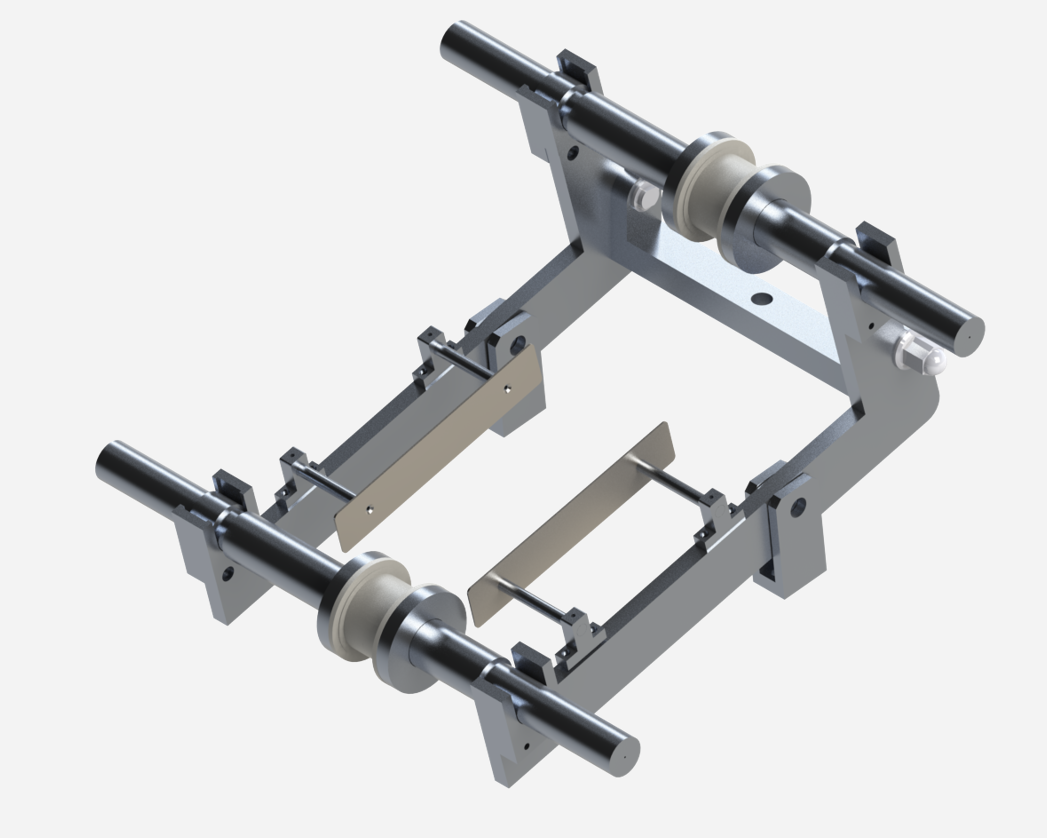

Pharmaceutical Package Design is not only about protecting and holding a product. It is also about guaranteeing its formation on the packing line in an automated way.

Designing a blister pack requires careful consideration of many factors. These include the;

- blister machine being used,

- products’ size & shape,

- material specification (traditional to new age sustainable).

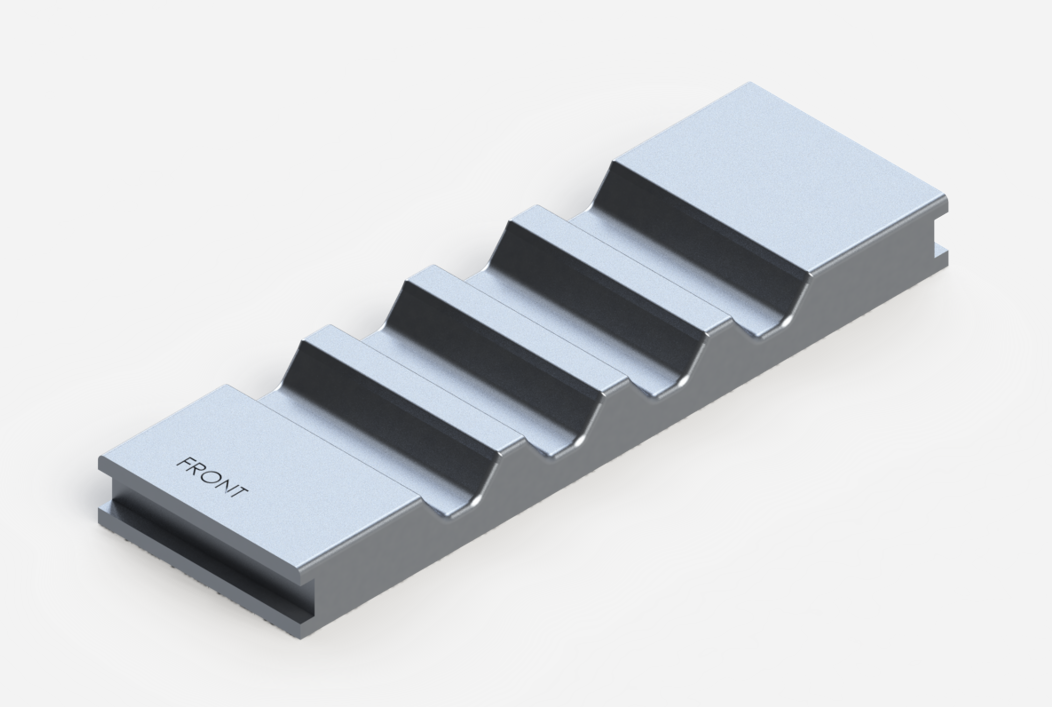

We use this information to design a new blister layout which is optimised for the desired pack size & orientation, pocket form, feed to pocket transition and requested output.

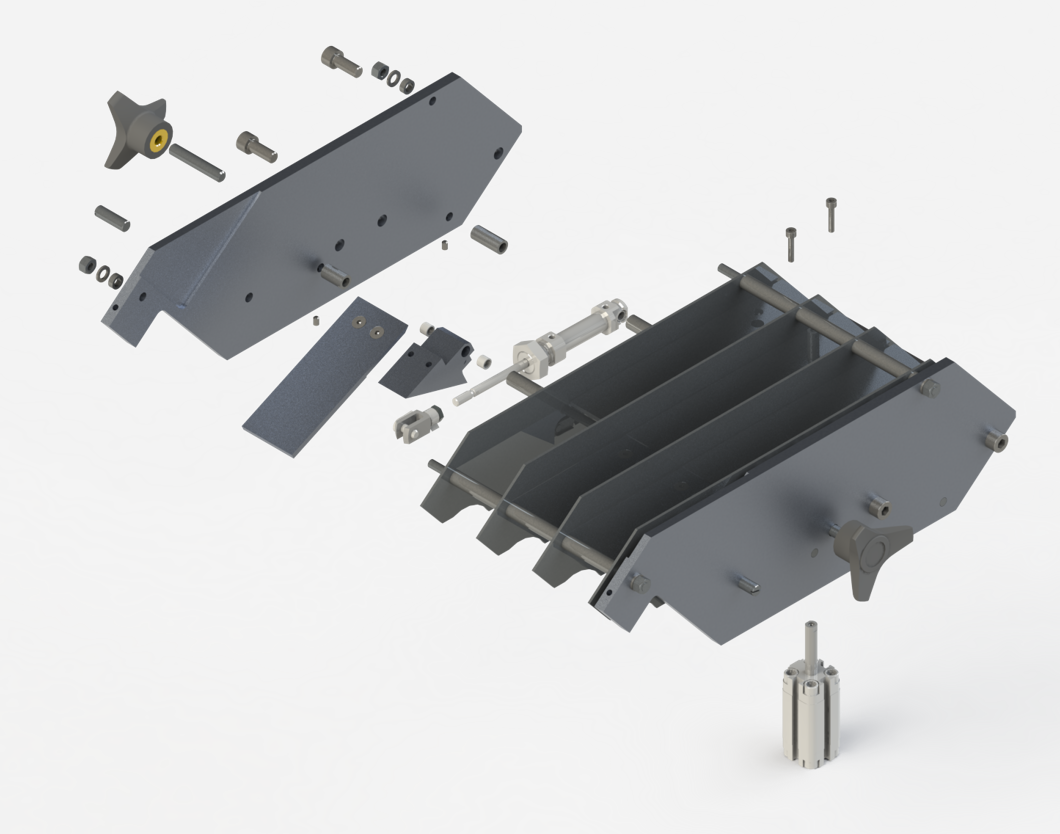

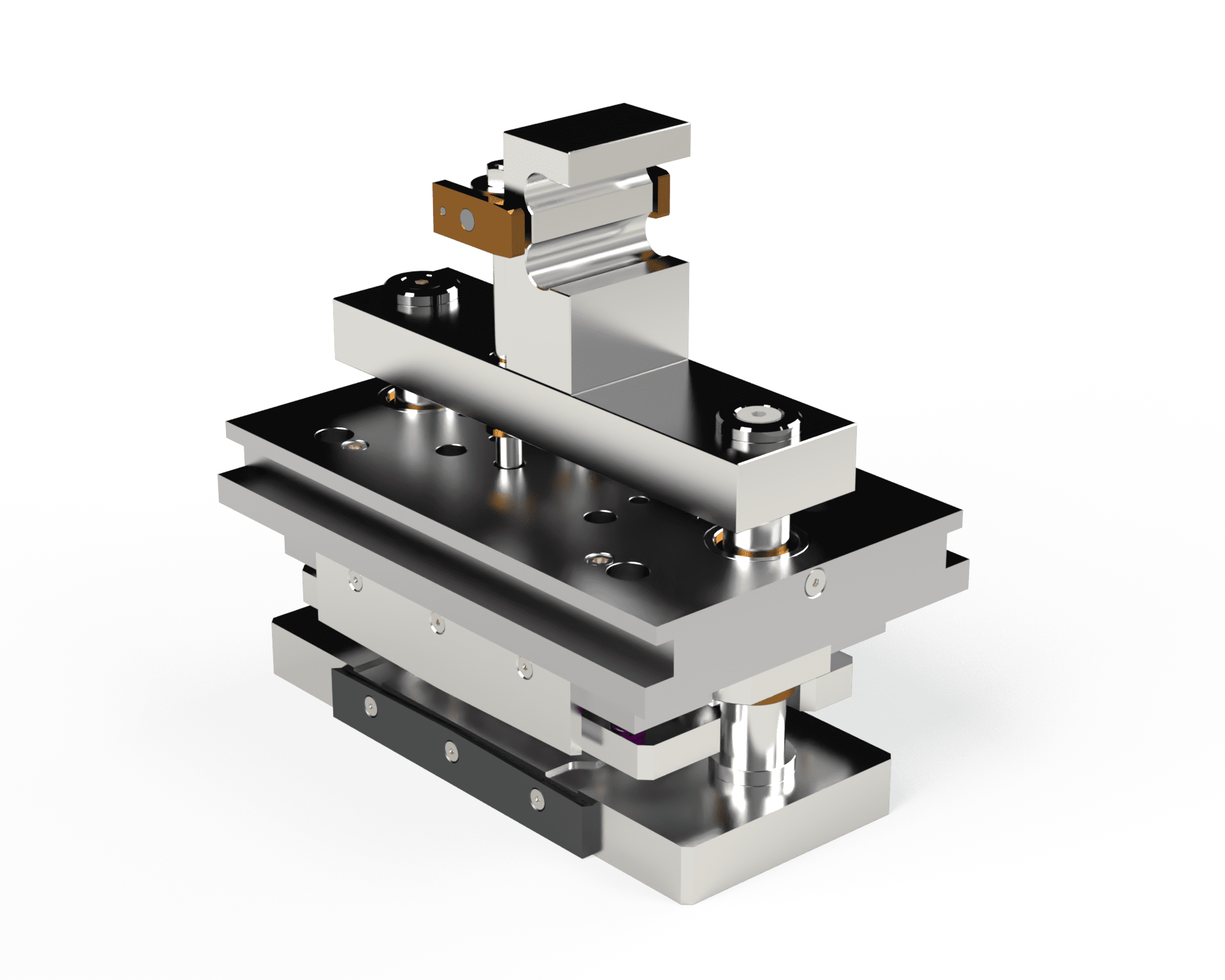

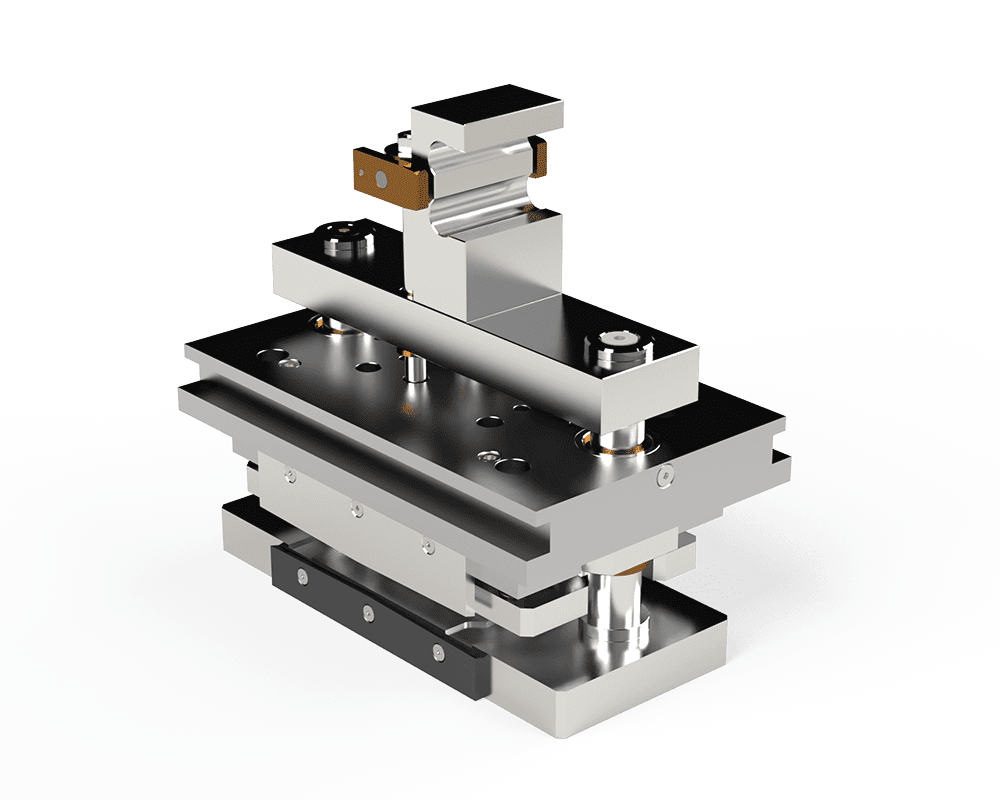

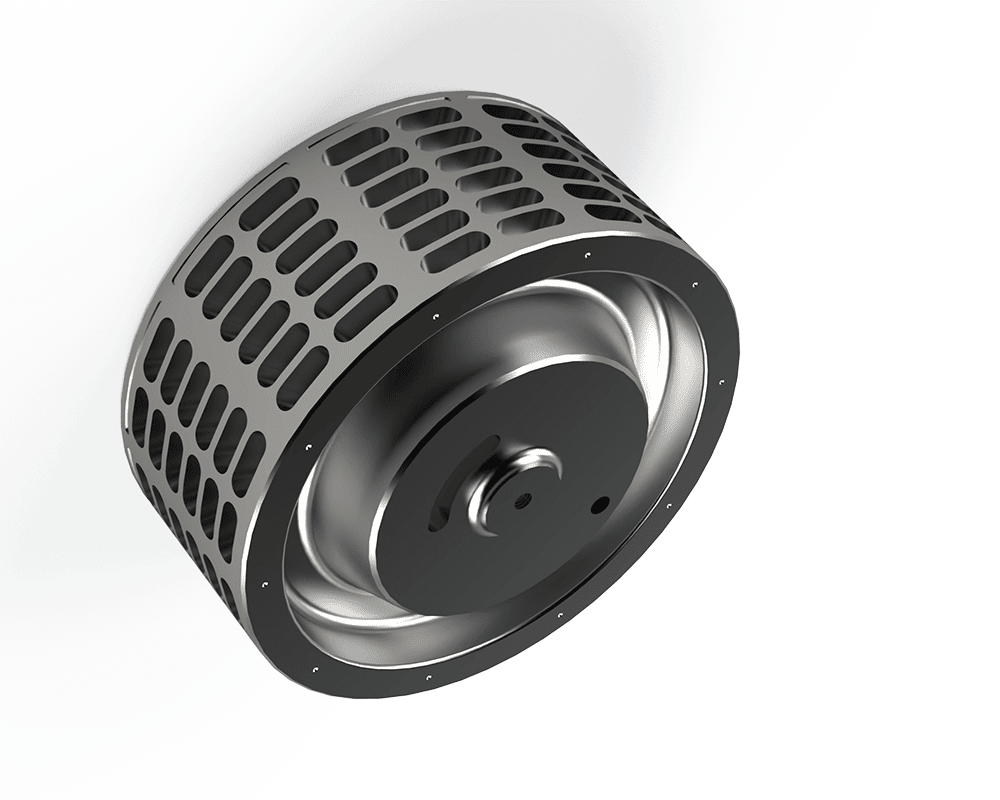

Once designed we can determine the tooling (new & existing) requirements to complete the pack.

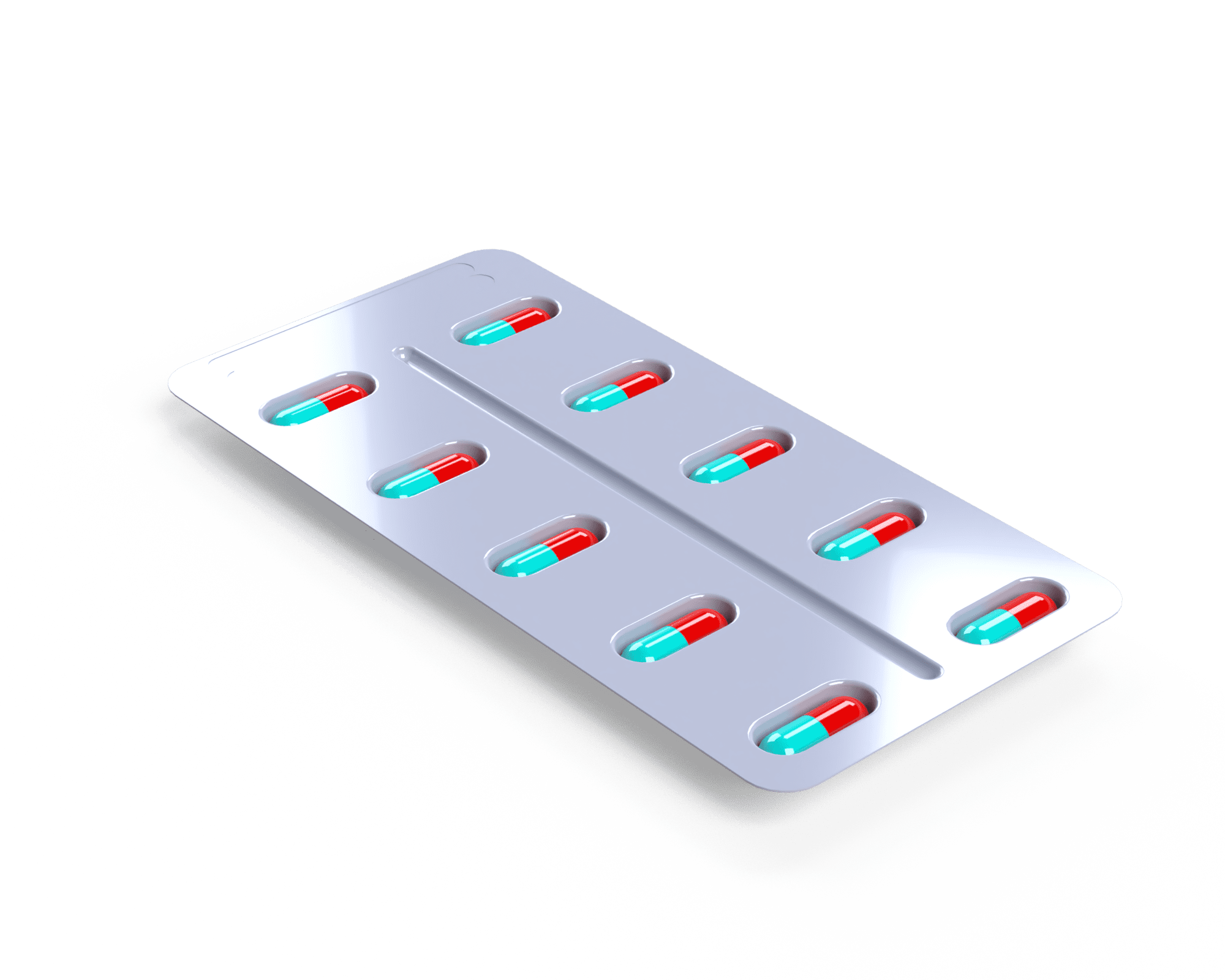

A new Blister layout

We look at the pocket design first (size, depth, product angle) to ensure a pocket can be formed and the product can feed into the cavity. We then optimise the product-per-blister, whilst checking there is enough seal area to create a blister pack which will pass a leak test.

Is it possible to blister pack anything?

We are always designing packs for tablets, hard and soft capsules of varying shapes and sizes. We get some strange and wonderful requests and usually we can design a pack in the same or next day!

‘’Could we blister pack anything? Well probably not!! Although, we have completed pack designs for complex shapes likes syringes, ampules, and vials. So, we are more than willing and happy to look at anything a customer needs to Blister pack.’’ says Steve Reed, Design Manager at Toolrite.

If you have a product which requires blister packing, feel free to contact us for support.