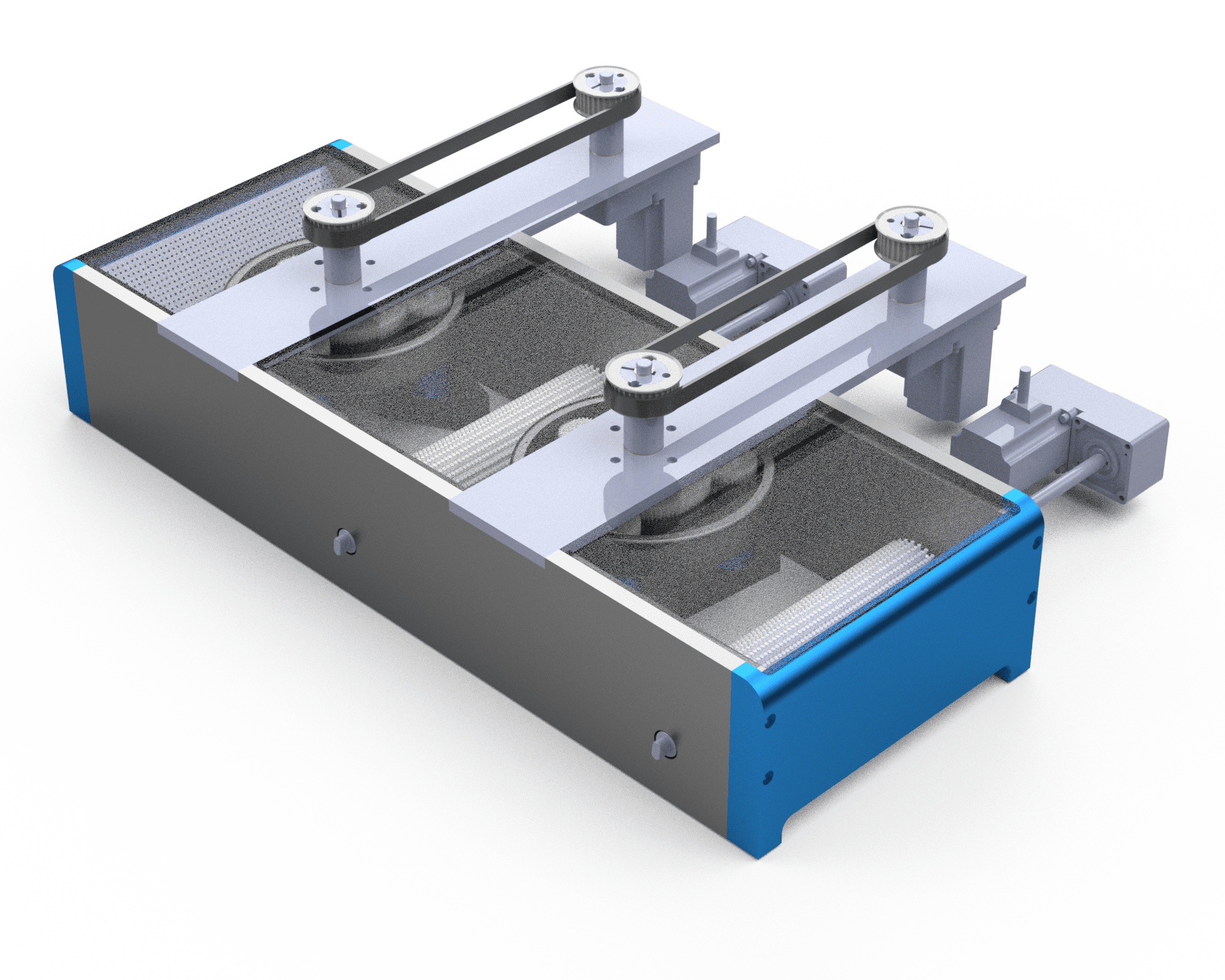

Sealing Station

Function: The sealing station brings together the filled form material, together with the foil where a combination of heat and pressure is used to seal the materials. After the sealing process is complete, the product is safely secured in the pack and can continue its journey down the line.

Toolrite Offering: By utilise intermittent motion platen sealing or continuous motion rotary sealing we can provide appropriate sealing tools for your packaging line.

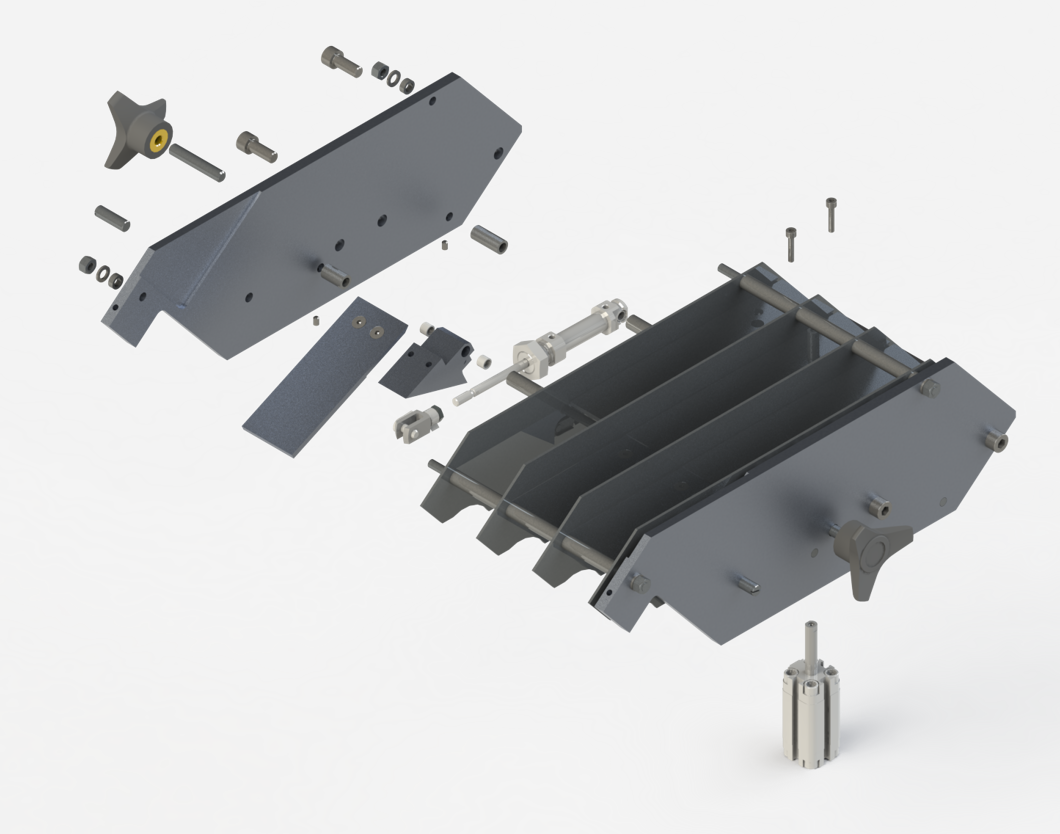

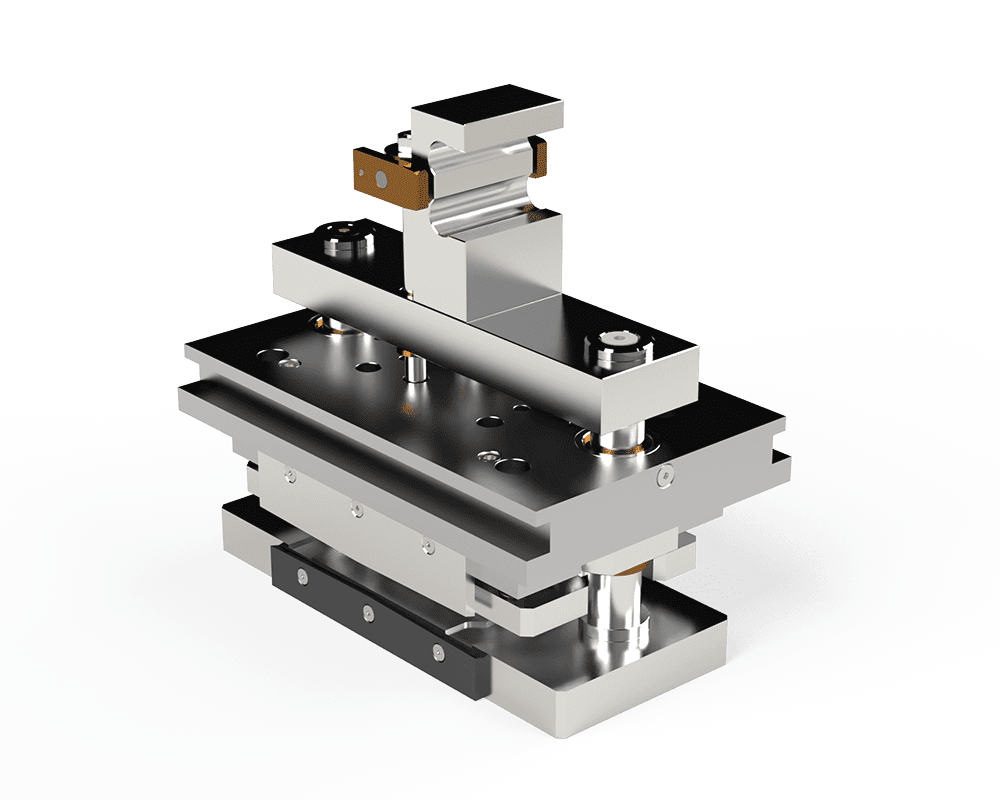

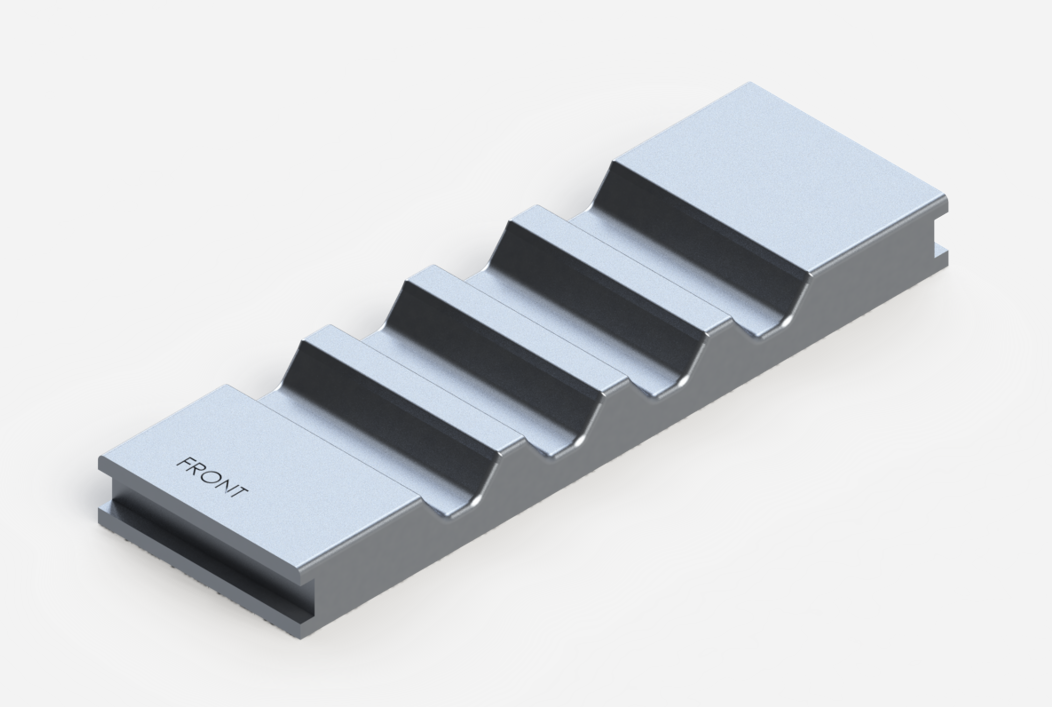

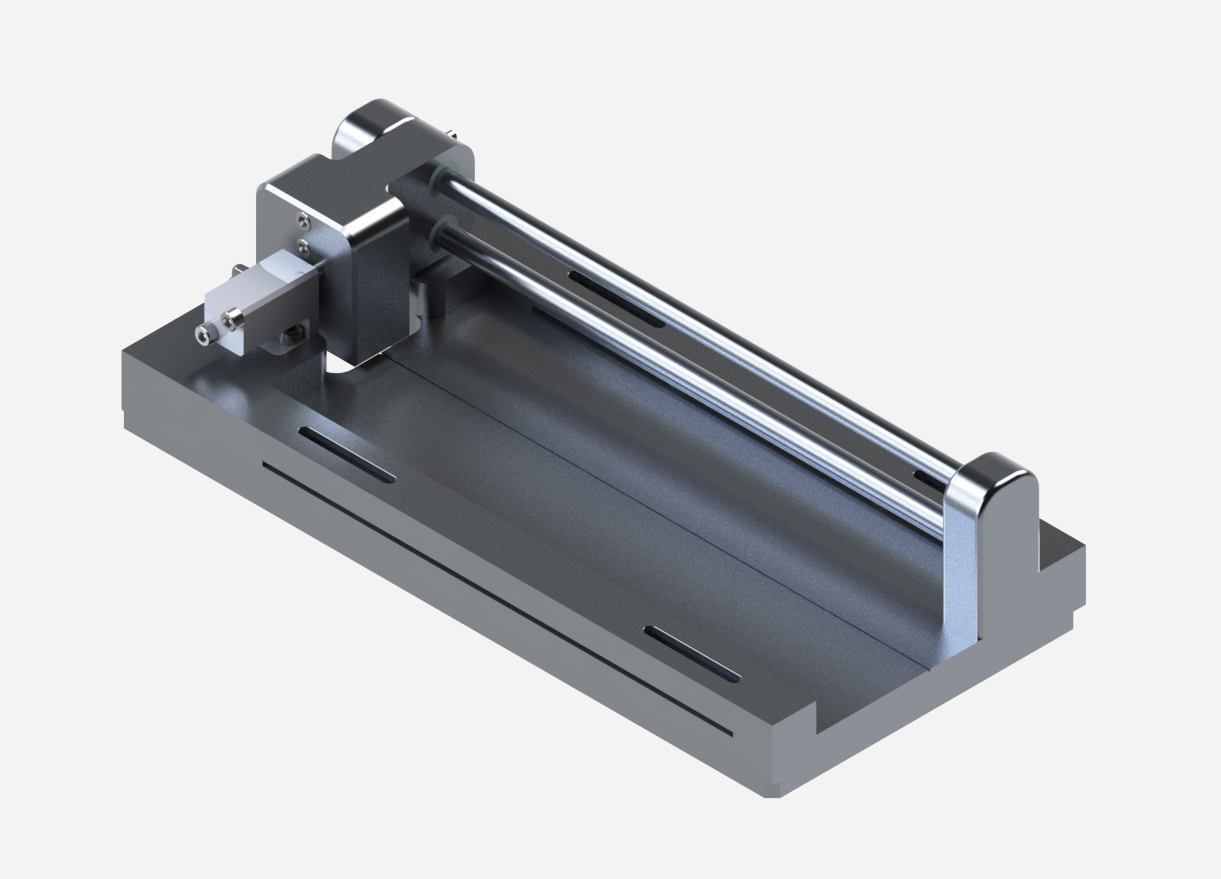

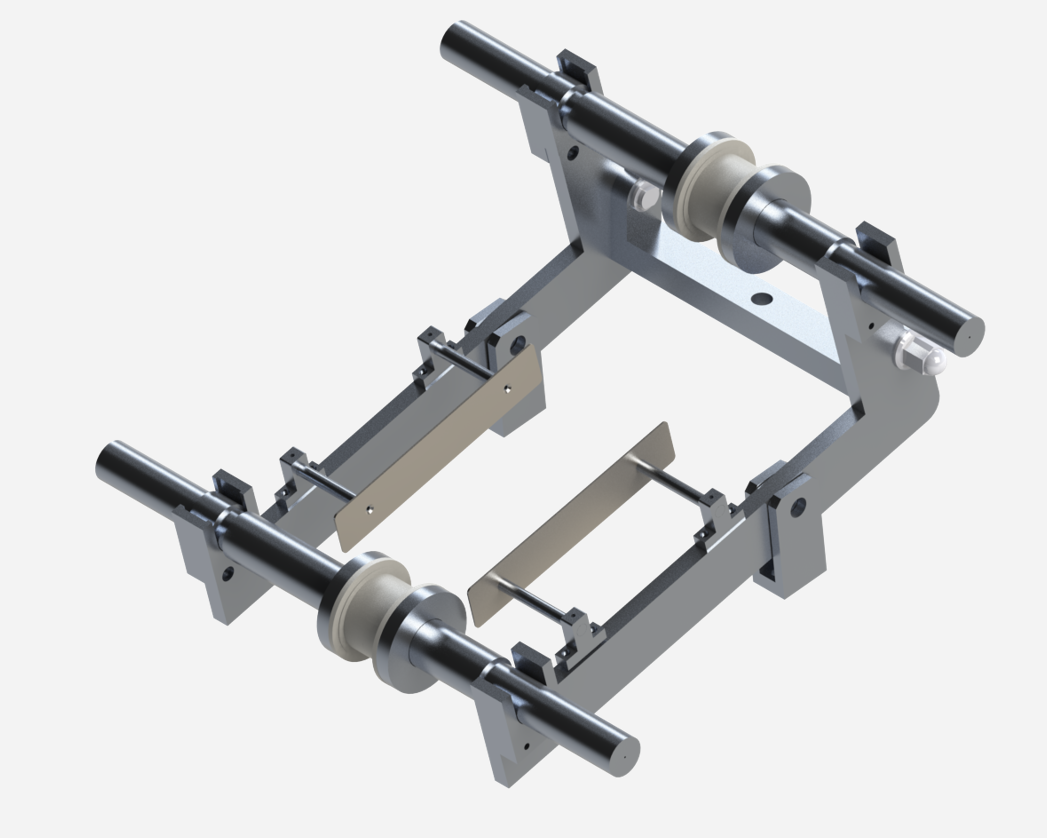

Platen Sealing

Platen sealing requires an upper and lower plate that are heated and come together intermittently to apply pressure resulting in a high quality seal between the two materials. We consider factors like seal flange widths to achieve a high quality seal.

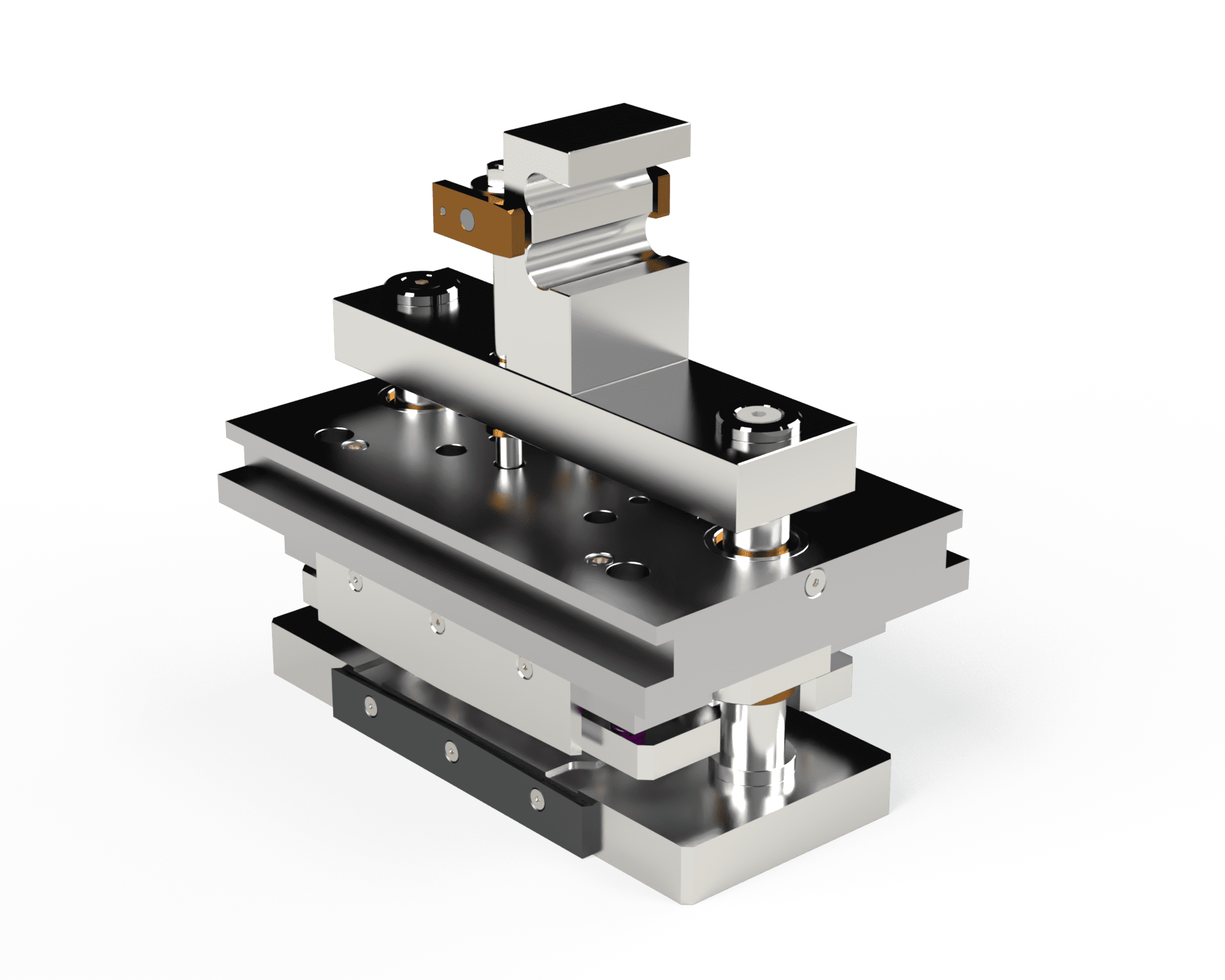

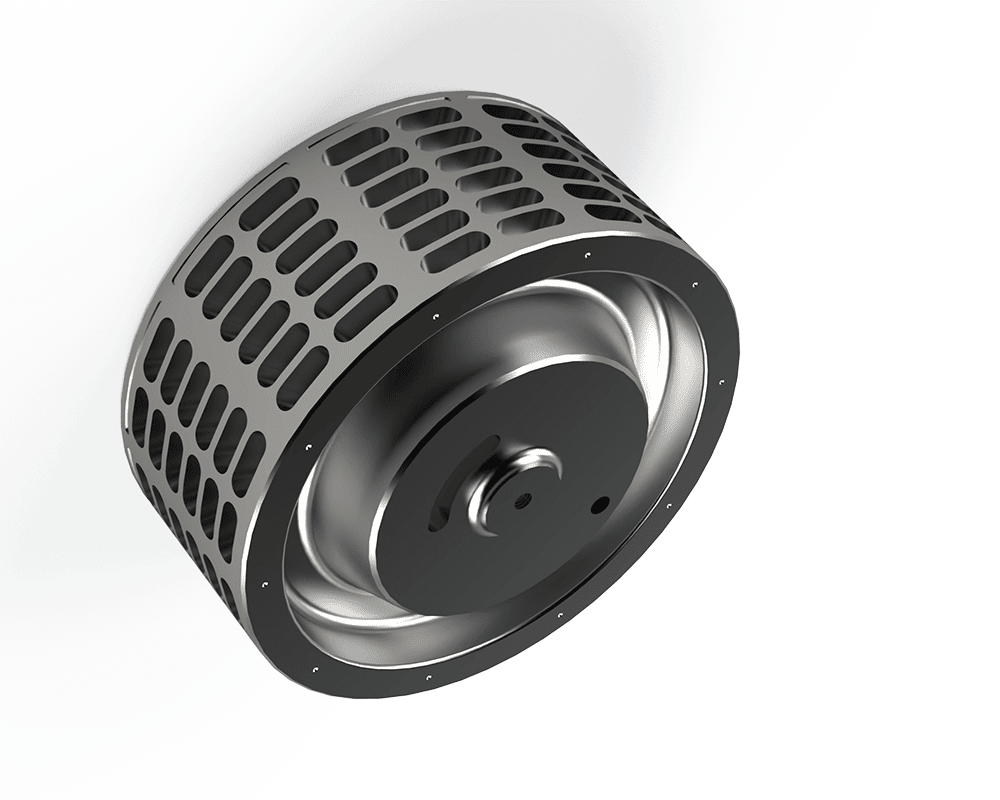

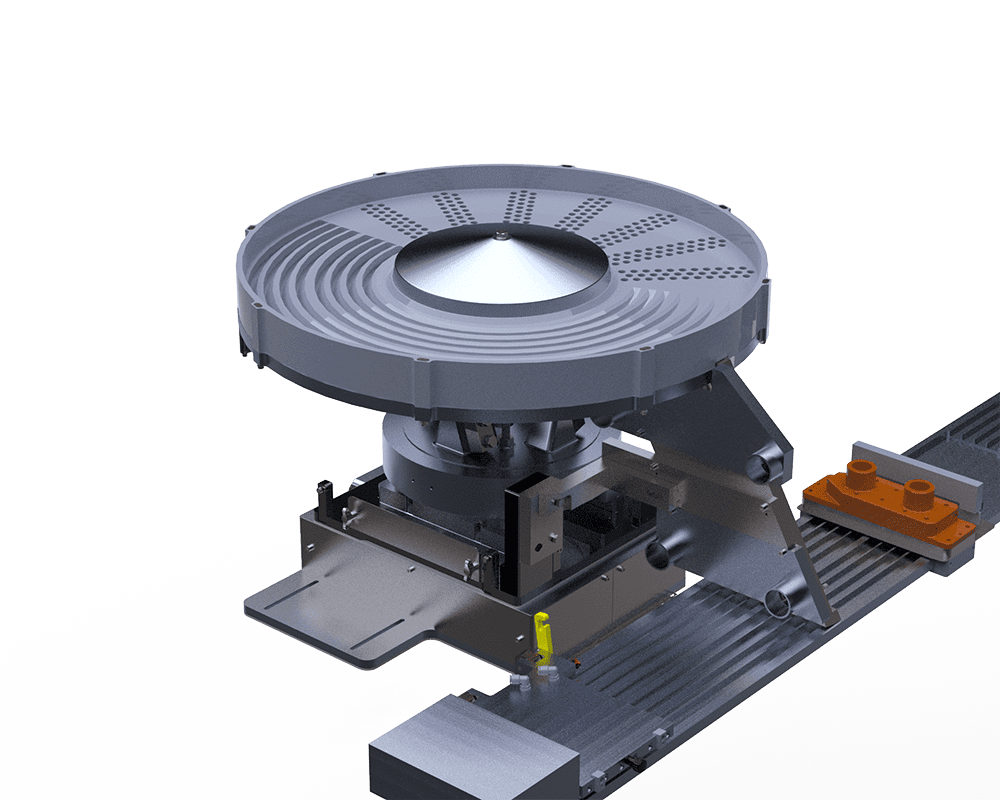

Rotary Sealing

Rotary Sealing utilises cylindrical tools to apply heat and pressure in a continuous motion to create a high quality seal. There are specific occasion when rotary sealing is selected.